Adventures in Composite Canoe Building, Part II: Jeckle

Randy Pfeifer maintains the Bear Mountain Boats Builders' Forum and is highly knowledgeable on the subject of woodstrip epoxy canoes. In this series, he documents his experiments building multiple canoes using composite materials, with the goal of creating a lightweight but fully functional Freedom 17.

In Part 1 of this series, the first canoe off the mold was unexpectedly heavy. With his second attempt, Randy begins the process of getting the weight down.

by Randy Pfeifer

With Jeckle sitting there at 24 pounds already I needed to stop being lazy with the off-the-shelf mentality and devise some weight savings tricks for the remainder of the Jeckle build.

I had already built an extra set of 3/8” thick bent foam ribs for Jeckle as I was bending them for Heckle. I threw them out. I set aside the 3/8” core I had tucked away. I looked for a thinner core thinking ¼”. I couldn’t find any ¼” thick foam material so I opted for two layers of 1/8” thick of 3 lb/cf foam and dispensed with the ribs entirely. I installed the core one layer at a time. Getting the 1/8” foam to conform to the shape of the hull was easy even without heating it. Total foam used was 2/3 cubic feet of lighter 3 lb/cf foam (2 pounds total). Instead of 5 oz Kevlar on the inside I used a lighter 2.2 oz Kevlar which of course absorbed less epoxy as well.

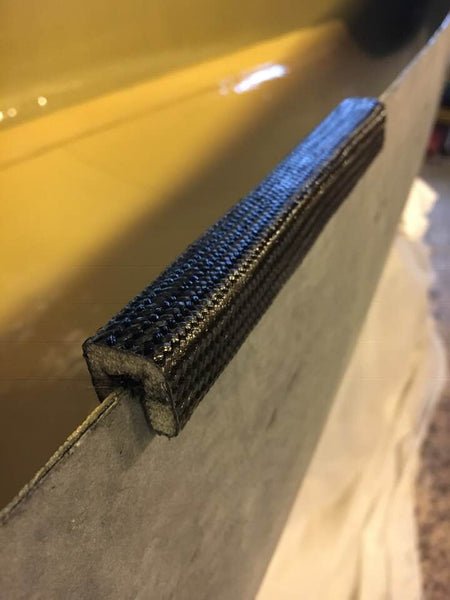

For gunwales, I built up a ¾” X ¾” foam strip 18’ long and cut a channel on the underside of it. That’s where the extra 3/8” thick foam I didn’t use on Jeckle’s core went). After rounding the corners, I pulled a carbon fiber sleeve over it and tucked the excess circumference of the sleeve into the slot. I taped some of the left over heat shrink plastic over the sheerline of Jeckle and pushed the gunwale over the sheerline after tapering the ends of the foam to allow for a nice joint between port and starboard gunwales at each end of the canoe. I wet out the carbon fiber sleeves in-place (isolating them from each other at the bow and stern). Once that set, the gunwales now had the correct shape and were pulled off the hull and the slot was filled with epoxy that was slightly thickened and then put back on the unprotected hull and glued in place for eternity. A small bit of weight was put on each gunwale to keep them in place while the epoxy set (this was a trivial task given the gunwales were already built to match the shape of the sheerline).

For seats, I built my own seats out of laminations of cherry steambent to a more comfortable shape with a layer of carbon fiber between the laminations for a bit of extra strength. They were laced with a nylon webbing used for making lightweight snowshoes.

The yoke was cut from a 5/4 thick piece of cedar and laminated between two layers of carbon fiber cloth for strength. Same yoke pads as Heckle. Same flotation chambers. Thwart and handholds were built with foam covered in a carbon fiber sleeve. Somewhat smaller skidplates but generally the same idea.

|

Jeckle weight |

Running total |

HULL |

|

24 |

24 |

Bare hull (carbon + Kevlar) |

|

4.35 |

28.35 |

Core + epoxy |

|

6.5 |

34.85 |

2.2 Oz Kevlar + epoxy |

|

|

|

TRIM |

|

3.34 0.56 |

38.19 38.75 |

Gunwales |

|

Seat mount brackets |

||

|

0.4 |

39.15 |

Thwart / hand holds / Flotation |

|

2.75 2.65 |

41.90 |

seats (incl bolts) |

|

44.55 |

Yoke (incl brackets/HW) |

|

|

0.55 |

45.10 |

Skid plate(s) |

|

-0.35 |

44.75 |

Hull sanding |

|

1.35 |

46.10 |

Varnish – sanding between coats |

|

Total Weight |

46.10 |

So, a savings of over 12 pounds! A bit of redemption. Still a lot of weight in the core. And maybe that 24 pounds in the first 3 layers could have been reduced….

I was left pondering if I would consider this experiment a success or not. I gave the 58 pound Heckle to my brother who was thrilled to have it. Success snatched from the jaws of disaster. And I could always replace the gunwales, seats and yoke on Heckle to reduce quite a bit of weight in the future. Not a lost cause by any means. I took 46 pound Jeckle into the wilderness of Algonquin Provincial park the week after the 2019 Bear Mountain Boats Rendezvous with a good friend. The portages in Algonquin are in general longer than those of Quetico. The pads I chose for the yoke on Jeckle were not the greatest. As I paddled and portaged, I got the feeling that Jeckle could still go on a diet and I decided to build yet another Freedom 17 composite to follow Jeckle. It had to be named Hyde.

New instalments in Randy's series will be published weekly - check back soon for Part III!